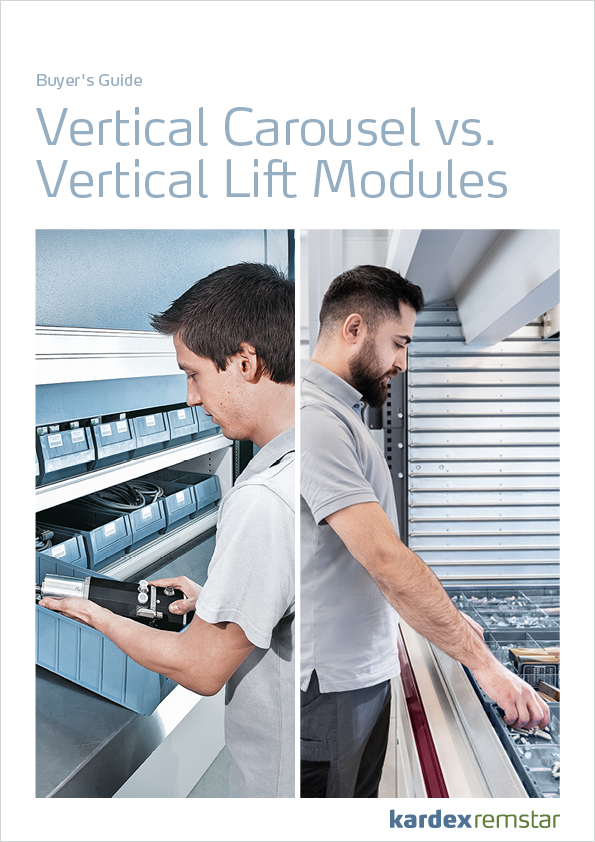

Vertical Lift Module (VLM)

The Vertical Lift Module (VLM) from Kardex features an enclosed shelf-based storage system designed to increase capacity in a more compact footprint.

Operating on the ‘goods-to-person’ principle, the VLM increases productivity by delivering goods directly to an operator. These systems are modular and flexible in design, which enables future adjustments for your business needs.

Warehouse requirements

- Save space and optimize room height

- Create an ergonomic working environment

- Secure stored goods

- Increase picking speed and accuracy

- Keep systems flexible

- Modular systems

Benefits at a glance

- More storage space/capacity in a smaller footprint

- Increased throughput

- Improved inventory control

- Expandable, scalable, and flexible

- Extremely safe and ergonomic

- Stored goods stay protected

How does the Vertical Lift Module work?

Kardex Shuttle models

Tab Navigation

Kardex Shuttle 250/500

Flexible solution for small parts and lightweight inventory

The Kardex Shuttle 250/500 is a flexible solution for storing and retrieving small-sized inventory. With a tray width of 4,050 mm, the Kardex Shuttle 250/500 can handle loads up to 560 kg per tray. It’s compact design allows it to adapt to space requirements, offering maximum storage capacity in a minimal footprint with a maximum height of 30 m. Further, the system easily modifies to a wide range of requirements. For example, for storing goods in temperature controlled units or under clean room conditions.

Kardex Shuttle 700

Highly compact storage for medium loads

The Kardex Shuttle 700 handles a tray width of 4,050 mm and loads up to 725 kg per tray. It adjusts to a device height of 20 m allowing a large storage volume. The Kardex Shuttle 700 is ideal for efficiently storing and retrieving heavy tools, components or spare parts. It is extremely flexible with a number of different options that can be easily integrated before or after installation. The units can expand, decrease, modify or adapt in various ways to cater to changing needs including business growth, new applications, or a relocation.

Kardex Shuttle 1000

Manages heavy duty loads up to 1,000 kg

With a tray width of 4,050 mm, the Kardex Shuttle 1000 loads up to 1,000 kg per tray. Achieving new load-carrying capacity standards, it's ideal for storing medium-heavy to heavy parts. Using a forklift, stack and store Euro pallets and mesh boxes in specially designed trays. This saves space and makes it possible to find goods faster, helping to lower costs, boost productivity and increase ergonomics. A factory-installed crane can be used to move stored goods easily, decreasing working times and costs.

Components for the perfect solution

The extractor moves the desired tray at high transport speeds directly to the access or back to an available storage location.

The lift door is included with the standard accessories of each unit to protect people, machines and stored items as well as to reduce noise and drafts.

Shelf rail modules hold the trays in the access opening. They can provide two trays at the same time, and work on different levels for optimum ergonomics of the operators.

If the safety light barrier in front of the access opening is activated, the unit stops moving immediately to protect the operator and the inventory.

Options for individual requirements

The wide range of add-ons (which can be integrated either before or after installation) provides even greater flexibility for the Kardex Shuttle. The following options are available:

-

Position indicator

-

Display LED-Navigator

-

Automatic/semi-automatic tray extraction

-

Tray extraction device for forklift operation

-

Double tray function

-

ESD Version

Position indicator

Display LED-Navigator

Automatic/semi-automatic tray extraction

Tray extraction device for forklift operation

Double tray function

ESD Version

Customized installations

Thanks to numerous options, the Kardex Shuttle provides flexibility for various needs. The system can be raised, shortened, moved to another location or adapted to new requirements.

Tab Navigation

Multilevel Installation

The Kardex Shuttle extends over several floor levels and is equipped with up to six access openings on the front and rear of the unit. This makes it possible to work on multiple levels simultaneously. For example, storing inventory and retrieving them at different access points.

Installation outside the building

To increase warehouse capacity, the Kardex Shuttle can be installed outside of a building with an additional enclosure. In this case, access to the stored goods is via an opening in the wall created especially for this purpose.

Maximize your success with integrated technology

Easily incorporate the following technologies

Fast and easy integration of barcode scanners for order picking, order identification, and the storage and retrieval process.

For faster order picking and consolidation, work zones can be connected via conveyor technology.

Easily integrate lifting equipment such as cranes for the ergonomic storage and retrieval of goods.

Automatic handling devices such as robots provide more automated storage and retrieval.

Every Kardex Shuttle is configured to meet your needs

Technical data of the Vertical Lift Module

| Kardex Shuttle 250/500 | Kardex Shuttle 700 | Kardex Shuttle 1000 | |

|---|---|---|---|

| Width | 1,580 to 4,380 mm | 1,580 to 4,380 mm | 1,580 to 4,380 mm |

| Depth | Spalte 1 2,312 to 3,074 mm | Spalte 1 2,363 to 3,125 mm | 2,363 to 4,343 mm |

| Height | 2,550 to 30,050 mm | 2,550 to 20,050 mm | 2,550 to 20,050 mm |

| Load | Up to 560 kg | Up to 725 kg | Up to 1,000 kg |

| Height grid | 100 mm | 100 mm | 100 mm |

Additional options

Kardex VLM Box – a solution customized for your business

The modular bin system made especially for the Vertical Lift Module is flexible in height, width and depth and the layout adapts whenever your storage needs change. With the Kardex VLM Box, it is possible to create over 300 different location types with just one dividing system.

Power Pick Software Solutions

Kardex Power Pick System

Kardex Power Pick System optimizes storage and retrieval in combination with Kardex machines. It covers multiple, smart picking strategies.

Power Pick Onboard

The Onboard inventory management software combined with automated storage and retrieval systems (ASRS), streamlines and accelerates warehouse processes.

Controlled environment

Inventory sometimes requires special storage conditions. Depending on your individual needs, we supply four optional controlled environment solutions. We integrate these into your storage and retrieval system and as a result, your sensitive goods are always protected.

Logicontrol 100/200

The machine-based control center enhances the usability of the automated storage and retrieval systems from Kardex. It provides a simple, intuitive touchscreen, user interface, and basic space management and reporting environment for the Kardex Shuttle. The new, state-of-the-art design is optimized for both touch and keyboard usage.